PV Analyzer I-V Curve Tracer

With the development of the renewable energies, and focusing on the photovoltaic solar energy, the installation of solar power plants has increased over the last years. This situation creates at the same time a demand over specific tools and devices that needs to develop at the same rate as these technologies.

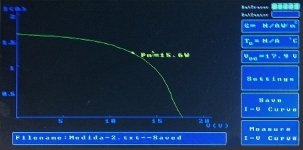

The best analysis method that can be applied on a solar power plant is the measurement of the I-V curve of the different modules. Any PV power plant installation will need at least one device to measure the I-V curve of the cells to make a proper monitoring of them.

The working principle of a capacitive load is not really a novelty by itself, but it needs to adapt to the incoming future by evolving according to the development of the current technology, making these systems faster, more efficient and effective in their use.

As a result a new type of capacitive load with new technology has been designed and assembled to satisfy the actual demand of the market. The system is composed by: one PV reference sensor that measures the irradiance and temperature; and the PV analyzer and I-V tracer that uses a capacitive load to measures the voltage and current of the desired PV module.

The system is a product that satisfies a real demand from the market and the industry that is constantly evolving. It also innovates, as it uses modern technology to create a very digitalized and autonomous device capable of measuring, interact and display the results without need of any other device.

The main characteristics to highlight are:

- Portability of the product, as it can run with the integrated battery without the need of an external power supply, allowing reaching remote places worldwide.

- Transmission of G and TC value by radiofrequency and automatic extrapolation of the measured curve to STC.

- Accurate measurements, with 12 bits of resolution (4096 values).

- High autonomy of the batteries, due to the reduced energy consumption.

- The interactivity of the touchscreen, that allows to display the measurements done, as well as compare this data with the one provided by the manufacturer. Everything can be done in the field test and it is easy to use.

- Reduced price compared with similar devices. The assembling cost of this device is around 800 euros. It can seem very expensive but the truth is that it is difficult to find in the market products with the same capabilities of this device, and the ones that achieve similar results have prices up to 6.000 dollars.

The profile of the customer that requires this kind of products are corporations that manufacture PV modules, investigation institutes and any company that develop the operation and maintenance of solar power plants independently of their size.